(Photos: J. Maus/BikePortland)

The Handmade Bike & Beer Fest got off to a solid start tonight in north Portland. This event, hosted by the Oregon Bicycle Constructors Assocation, has teamed up with the Oregon Brewer’s Guild this year to offer a wider variety of craft beers to go along with the craft bikes.

I took a walk around the show floor to meet a few of the builders and get a closer look at what they had to offer…

Breadwinner’s Special Edition “Take the Long Way Home” B-Road

Tony Pereira and Ira Ryan of Breadwinner Cycles brought something new to the show this year: a special edition of their “B-Road” model that will only be on sale until October 21st.

“We built and designed this as our gravel bike,” Pereira shared with me at the show tonight, “but it’s really our most versatile bike. It’s a quiver killer. If you can only have one bike it’d be a good one to have.”

This special B-Road comes with a new colorway, matching frame pump and all the features and spec that have made this such a popular bike: room for cushy 44 mm tires (or 32 mm with fenders), USA made components from Chris King and Thompson, disc brakes, stainless thru-axle dropouts, handbuilt wheels from Sugar Wheel Works, rack and fender braze-ons, Silca Super Pista Frame Pump painted to match, Brooks saddle, Shimano Ultegra groupset, and more.

Price is $5,695 and delivery is guaranteed before Christmas if you get your order in by October 21st. Learn more on their website.

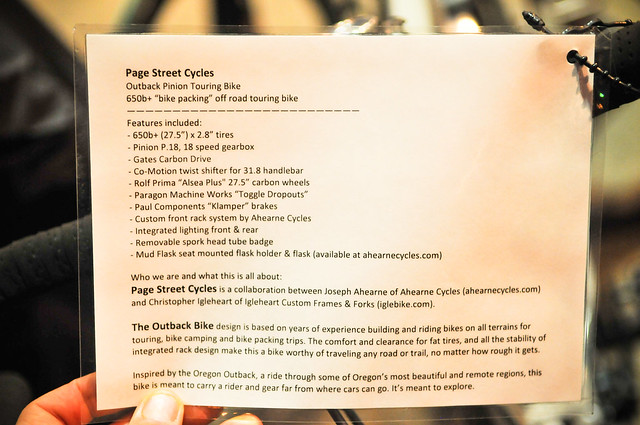

Introducing Page Street Cycles

Joseph Ahearne (Ahearne Cycles) and Christopher Igleheart (Igleheart Custom Frames and Forks) have well over half a century of bike building experience between them. They’ve also shared a shop on North Page Street for the past five years. As the two have started working on projects together (like a recent batch of six bikes for Box Dog Bikes in San Francisco) it was a natural move to start up a new brand.

Page Street Cycles is the official name of their new collaboration and so far we like what we see. Ahearne’s brazing and rack-making combines perfectly with Igleheart’s TIG welding and expertise in fork making. And both builders’ quirky yet classy approach to bike making plays very well together. They displayed two Page Street adventure bikes that looked like they were ready for anything.

Advertisement

Supplying the trade

Portlander Tony Tapay is the man who sells the ingredients used in the concoctions these bicycle craftsmen cook up. Tapay is the owner of Framebuilder Supply, a company that sells tubing, lugs, and other frame parts.

After giving framebuilding a try himself several years ago, Tapay found that just getting the raw materials he needed from a local source was a pain. Building bikes was also very hard work that he couldn’t see ever scaling up into a long career. “So I decided I wanted to be Levi Strauss. He once said that, ‘I can be a gold miner, or I can sell jeans to gold miners.'”

Two years ago Tapay launched Framebuilder Supply and the business has seen strong growth ever since.

Framebuilder Supply has clients all over the country ranging from well-known small builders like Breadwinner and English, to garage hobbyists who just build a frame or two.

Building bikes in the Cully neighborhood

John Norstog is the man behind Thursday Bicycles. He lives on a half-acre in the Cully Neighborhood of northeast Portland where he builds a wide range of bicycles — from his backcountry-ready “Elk Hunter” model to youth BMX bikes.

“I have a narrative approach to building,” Norstog shared with me. “Every bicycle I build has a different story.”

Norstog is a retired employee of the Navajo Nation in Idaho where he advised the president of the tribe. Asked how the name “Thursday Bicycles” came about, he said, “Thursday was always a slow day on the reservation, so I’d go home and build bikes.”

A unique manufacturing approach

Rich Fox hasn’t stopped chasing his bike making dreams since he launched Circa Cycles two years ago.

His unique approach relies on aluminum tubing that’s bonded with aerospace grade structural adhesive to proprietary lugs. His manufacturing process is much quicker and cheaper than traditional methods because his building process doesn’t require heat (no welding), paint (his frames are anodized), heavy tooling, or excessive labor. He estimates he can build a complete, custom-fit bike in less than 10 hours — five to ten times quicker than a traditional framebuilder.

Fox sees himself as a systems and product platform developer instead of a craftsman. Using a trackpad instead of a torch, he leans on his background as a designer at Nike and Ziba. Circa has a showroom in northwest Portland where customers can pick their style and colors and get a fully custom bike delivered in less than two weeks.

These are just a few of the builders and bikes you can see at the Handmade Bike & Beer Fest. The show is on all day tomorrow (10/8) at the North Warehouse (723 N Tillamook Street at Interstate). See the event website for more details.

CORRECTION: We Misspelled John Nortstog’s name in the original post. We regret the error.

— Jonathan Maus, (503) 706-8804 – jonathan@bikeportland.org

BikePortland is supported by the community (that means you!). Please become a subscriber or make a donation today.