Ken Wheeler is teaching an old material new tricks — and in the process, he’s doing something that is literally on the cutting edge of framebuilding.

Wheeler, under the name Renovo Hardwood Bicycles, is producing hollow, monocoque bicycle frames out of exotic hardwoods using a CNC machining process (CNC on Wikipedia).

After I noticed his name on the list of exhibitors for the upcoming North American Handmade Bicycle Show (NAHBS), I had to pay him a visit. What I saw was surprising and impressive.

Wheeler, who has ridden bikes his entire life, is the former owner and CEO of a 75-employee business that designed and produced composite airplanes in Gig Harbor, Washington. Three years ago, he moved on from that company and came to Portland (from Seattle) to start up a wood carpentry business making high-quality, wooden camp kitchens, fly-fishing tackle boxes, and other items.

One day, Wheeler leaned his bike up against his CNC machine and the light bulb went off: “I wondered to myself…could I build a bike?”

Wheeler is no stranger to high-end wood and metal fabrication. While touring his shop, he pointed out a poster of Italian-made “Falco” wooden airplanes that he admires and he is a veteran aircraft mechanic with years of metalwork and welding under his belt.

Fast forward to last summer and Wheeler had made his first prototype CNC’d wooden bicycle. “That proved the concept,” he said, “and I’ve been testing, researching, and building ever since.”

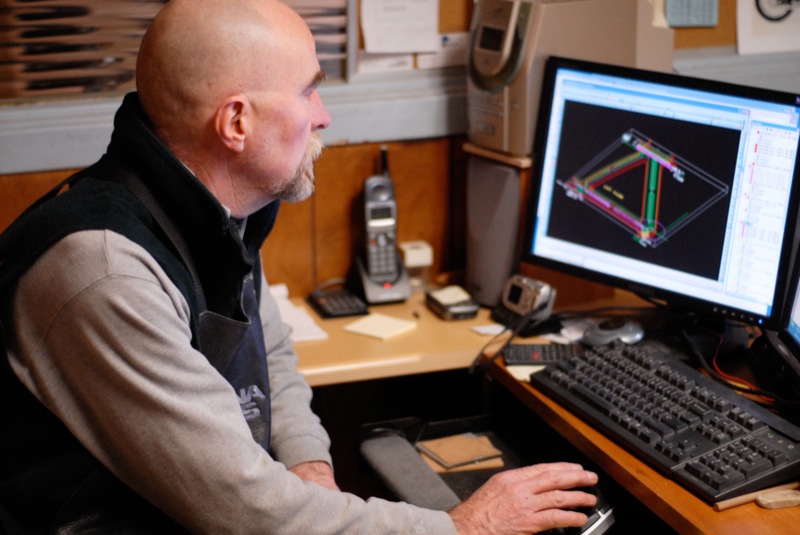

Also during my visit, I watched Wheeler do a test run on the CNC machine (he runs plywood through first to make sure his calculations are accurate). I was stunned. I watched a CNC machine hover over the slab of wood with hard edges and no finish work yet done on it. It whirred and cut with absolute precision, perfectly rounding edges and hollowing out the wood.

Wheeler looked at me and said, “It should done in about five or six minutes.”

This was a stark contrast to the painstaking work I’ve watched in other local shops, where framebuilders hunch over one weld, tirelessly sanding steel for hours on end.

Was I witness to the beginning of a framebuilding revolution?

Wheeler says he’s identified 53 different hardwoods that have the hardness, elasticity, machinability, and other characteristics necessary for making bicycles. Some of his favorites include Brazilian cherry, vertical grain fir, jatoba, and purple heart. All the wood is either FSC certified or is sustainable and plantation-grown

He’s put his wooden tubing samples up against Easton aluminum. The result? “We beat aluminum every time,” Wheeler says with a smile.

But can his hardwood bikes — which can weigh as little as 16 pounds fully built — beat the competition? Wheeler’s friend Joe Hall, a professional triathlete, will ride a Renovo in the Hawaiian Ironman competition this summer and Gateway Bicycles owner Keith Willis claims the bike is “Cervelo quality.”

Wheeler has big plans for Renovo. “The way these are made lends itself to high volume production.” He’ll debut them to the world tomorrow at the NAHBS, and he plans to attend Interbike later this year.

Check out RenovoBikes.com for more information.

— Jonathan Maus: (503) 706-8804, @jonathan_maus on Twitter and jonathan@bikeportland.org

BikePortland is supported by the community (that means you!). Please become a subscriber or make a donation today.